Biogas Plants

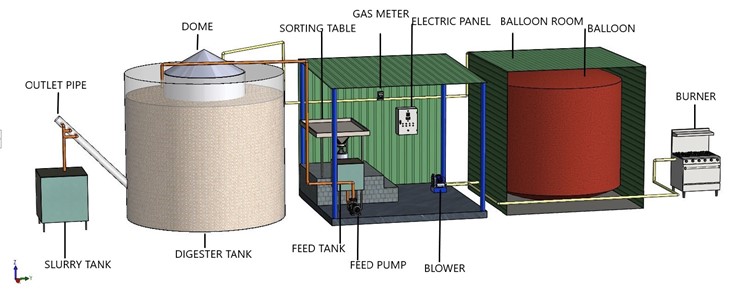

Biogas Plants process various organic wastes from kitchens, livestock farming, and food industry and convert it into energy rich gas, electric power and organic fertilizer. Anaerobic digestion (without oxygen) of organic substrates is the scientific base of the biogas technology wherein the biogas (Methane: 60-70%, Carbon Dioxide: 30-35% and small proportion of H2S, N2 and H2) is produced. This biogas can be utilized as a cooking fuel or can be used for electricity generation.

FuelAlts has in depth expertise of the technology acquired from the reputed national institutes and has ability to execute end to end project at pan India level.

Biogas plant features:

- Eco-Friendly: Zero emissions of greenhouse gases. The process lowers methane and other gases by entrapping and using as fuel.

- Electricity Generation: Biogas used as fuel for combustion engines, powering an electric generator to produce electricity.

- Green Energy Source: Biogas acts as green energy. Helps in reduction in usage of non-renewable energy sources like coal, fossil fuels etc.

- Alternate Cooking Gas: Biofuel generated can be used for cooking as it burns cleanly & produces fewer pollutants.

- Bio-CNG: Can be used as Automobile fuel for vehicles.

- Organic Fertilizer: By-product is an enriched organic fertilizer, best substitute for chemicals for agriculture.

Commercial Biogas Plants

We offer wide range of commercial biogas plants starting from 5 m3 to 30000 m3 biogas production per day. FuelAlts undertake effective projects only after analyzing the specific needs of our clients. We customizes the capacity, the design and the material make completely based on individual client’s site location, weather condition, budget allocation, etc.

FuelAlts Biogas team of qualified and experienced professionals comprised of Engineers, Biologists, Doctorates, Business management specialists and technocrats accompanies the client at every step of the project, starting from planning phase to construction down to the start-up of the biogas plant till its stabilization.

We monitor various parameters in samples from biogas collected for better matching the services of operation in order to improve the performance of extraction and upgrading of biogas equipment. When necessary, we carry out detailed analysis of specific parameters through accredited laboratories.

The vast experience accumulated in the operation and maintenance of Biogas power/ Bio CNG plants, the permanent availability of technicians and spare parts, or even the ability to daily operate on the field, in the case of biogas recovery plants, are factors that allow us ensure responding to any service request in a short time and with high levels of plant availability.

Anaerobic Digester Types

- Continuous Stirred Tank Reactor (CSTR)

- Two Stage Anaerobic Digesters

- Single Stage Anaerobic Digesters

- Fixed Dome type biogas plant